A Unique Silk Production in Thailand

The Silk

Sericulture

The knowledge and skill of preparing silk yarn and weaving fabric is a craft passed down through many generations. No toxic chemicals or industrial machines are used. The dry soil of north-eastern Thailand is excellent for growing mulberry trees. Silk worms thrive on the leaves of these trees creating the strong Sen-Hua and Sen-Lue silk yarns essential to the durability and quality of the silk fabric produced for LEA SILK.

Léa Silk production begins with village weavers breeding and placing silkworms on trays of mulberry leaves where the worms consume 25,000 times their original weight in leaves during a 40-day period. Then the silkworms commence spinning their cocoons. The partially formed cocoons are transferred to twig bundles where cocoon spinning takes another week to complete.

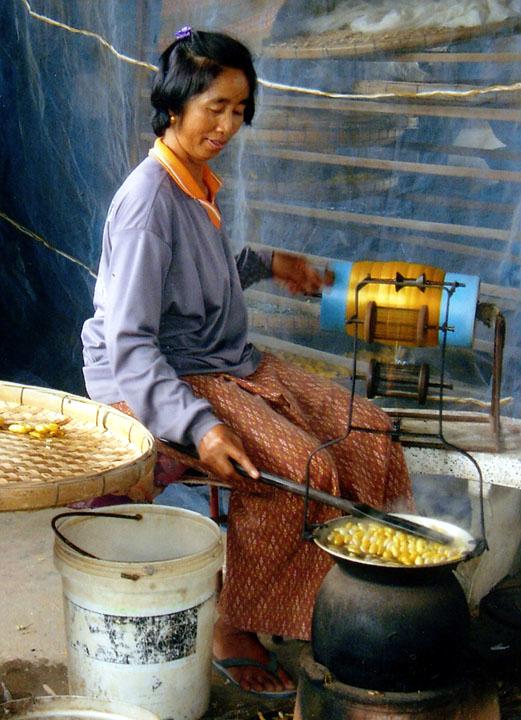

Raw Silk Yarn

Completed cocoons are unravelled in boiling water and the resulting raw silk yarn placed outdoors to dry naturally. The raw yarn’s natural colouring ranges from light beige to bright yellow. The raw yarn is not bleached to maintain its strength. When dry the yarn is immersed in a liquid made by running boiling water over the ashes of coconut husks and banana leaves. This process removes Sericin, a natural stiffening substance, from raw silk fibre. Hung and dried again, the raw silk is ready for dyeing. Colours are selected to compliment the silk yarn’s natural hues.

Dyeing and Weaving

Only vegetable and non-toxic chemical dyes are used to ensure the silk fibres are not damaged or spoilt. Traditional methods of dyeing involve immersing the raw silk in a carefully prepared dye solution to ensure consistent penetration that is the hallmark of the lustrous Léa Silk colours. Once dyed, hung outdoors, and dried, the silk yarn is reeled onto spools under tension and stored until needed in the weaving process as warp or weft yarns.

When needed as warp, the dyed yarn is unwound from its spool through a warp comb which converts yarn into equal lengths of warp thread. Warp ends are then inserted into a weaving comb, thread by thread. The weaving comb is mounted on a loom where the warp is interwoven with a corresponding weft--similarly processed, but with threads being thinner than the warp. A weaver can produce half a meter of silk fabric in five hours.

Solar Dyeing

Developed by Léa, this innovative dyeing process combines the dyes with a fixative which reacts to sunlight. Raw silk warp yarns are exposed under tension in direct sunlight at lengths of 20 to 40 meters from the warp comb onto which the yarn ends are inserted. A group of weavers, each with a pot of an individual dye colour, use paintbrushes to apply their dyes to the threads at random. Sunlight fixes the colour in eight hours. When dyed warp yarns are interwoven with similar weft yarns, a silk fabric with a subtle yet dazzling rainbow effect is produced. A variation of solar dyeing is where Ms. Léa applies a unique design to a length of raw silk fabric stretched in direct sunlight. After a six-hour fixing period, an original length of beautiful and unique hand-painted silk fabric is the result.

Quality Control

Fabric production requires great care to ensure uniformity of weft thickness and spacing and that borders are straight. Careful inspection of finished silk fabric ensures there are no broken warp threads, holes, or contamination by foreign particles marring the quality and stunning appearance of Léa Silk fabrics.